S Series dredge sand pumps are designed to handle very large particles for gravel and dredging operations. This sand pumps are designed for continuous handling of the most difficult higher abrasive slurry, containing solids too large to be pumped by a standard slurry pump.

S series dredge sand pumps are suitable for delivering slurry in mining, explosive sludge in metal melting, grudging in dredger and course of river and other fields.

sand gravel pump assembly in factory

1) Impeller — Pump out vanes on rear and front (on closed impellers) reduce recirculation within pump, and aid in preventing seal contamination

2) NPSH — Exceptional NPSHr conditions due to large impeller eyes

3) Large Particles — Large eye openings and vane passages allow for the largest particle flows

4) Expeller (Centrifugal Seal) — Available with low flow water flush or zero flow (grease lubricated) options to provide exceptional sealing where water introduction to the seal is intolerable or limited

5) Stuffing Box — Gland sealing with packing and lantern ring

6) Bearing assembly — A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

8) Frame Base –A very robust one piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

2) NPSH — Exceptional NPSHr conditions due to large impeller eyes

3) Large Particles — Large eye openings and vane passages allow for the largest particle flows

4) Expeller (Centrifugal Seal) — Available with low flow water flush or zero flow (grease lubricated) options to provide exceptional sealing where water introduction to the seal is intolerable or limited

5) Stuffing Box — Gland sealing with packing and lantern ring

6) Bearing assembly — A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

8) Frame Base –A very robust one piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

Wet parts of this kind sand pump-impeller, liner and front&back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features.

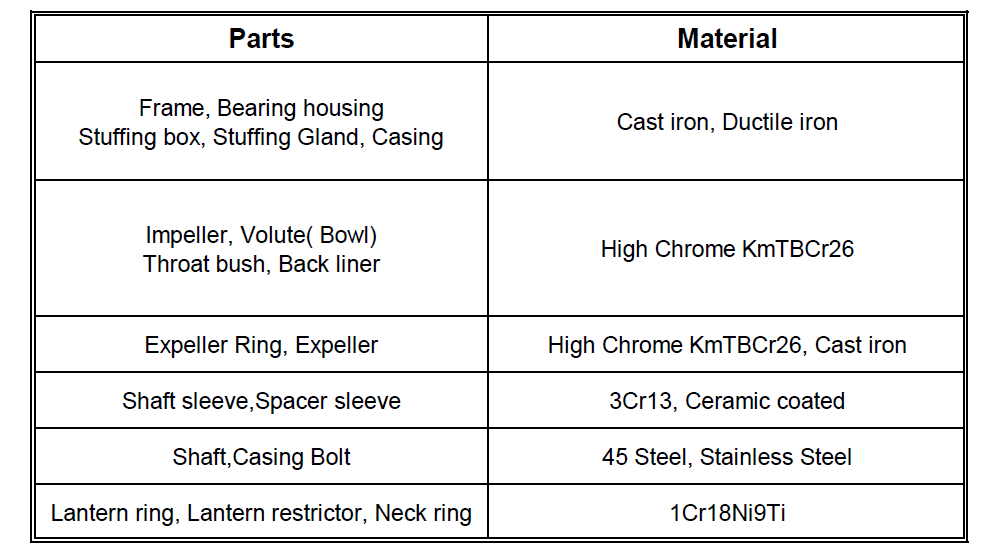

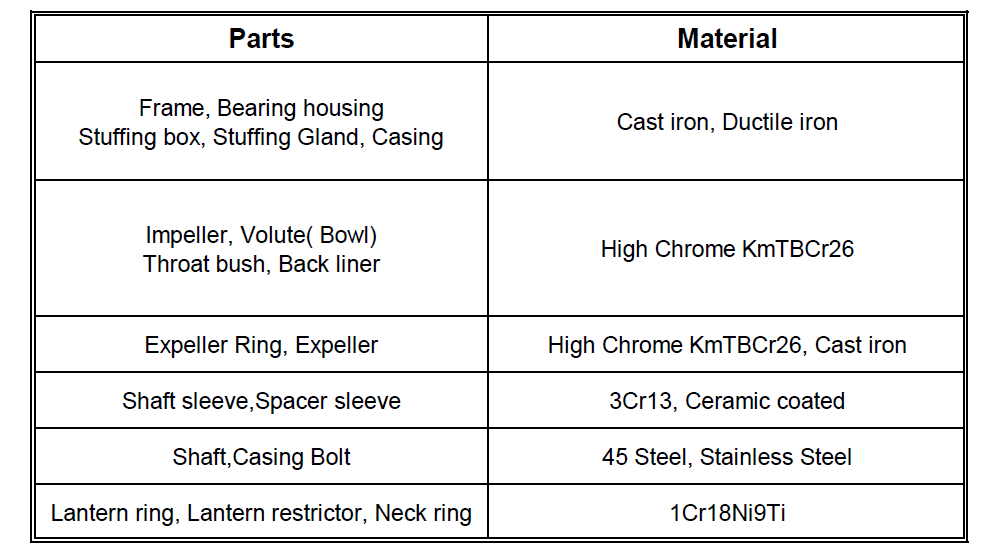

Sand gravel pump Material