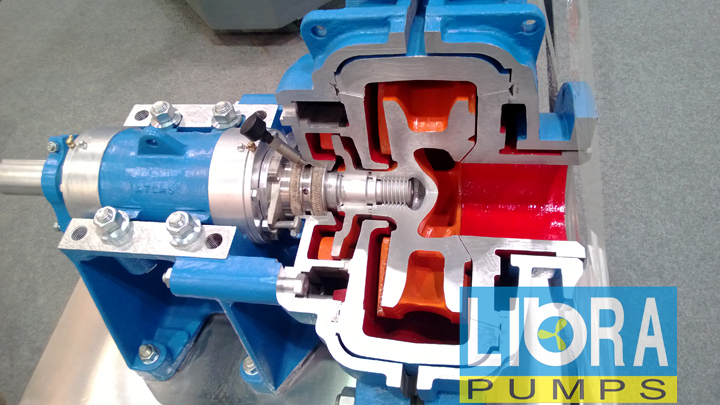

Better structure is one way to mitigate slurry pump wear. Such as double casing, thicker liner and impeller, add vanes and expellercan also reduce the wear and tear. According to the the slurry specific, the double-casing or single-casing structure slurry pump can be selected.

When higher specific gravity or coarser solid particles contained in the slurry, double-casing structure slurry pump is more suitable, at the same time should be with the easy removal structure.

Single-casing slurry pump is smaller and lighter, also can be used for some condition.

In addition, the operating conditions have a large impact on wear of slurry pump, if the working flow is less than the designed flow, Impeller wear is relatively light. So that we should design a bit higher flow than working required, in order to reduce the wear and tear of the slurry pump.