Thermal power plant slurry pump / FGD Pump

FGD Pump just done for power plant

Environment problem is serious day by day, and thermal power plant is a factor for air pollution for all the time. In order to decline the pollution, FGD pump is one choice.

A thermal power station is a power station in which heat energy is converted to electric power. Certain thermal power stations also are designed to produce heat energy for industrial purposes, or district heating, or desalination of water, in addition to generating electrical power.

FGD is short for Flue-gas desulfurization. It is a set of technologies used to remove sulfur dioxide (SO2) from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting.

SO2 is an acid gas, and, therefore, the typical sorbent slurries or other materials used to remove the SO2 from the flue gases are alkaline, mostly will be CaSO3 (calcium sulfite) also know as limestone.

In this case, the slurry in usage will be corrosion, so the pump need to have corrosion and wear resistance performance. Here bellow we do the in high chrome, can deal with Ph 3 to 12, very good material and widely used in FGD pumps.

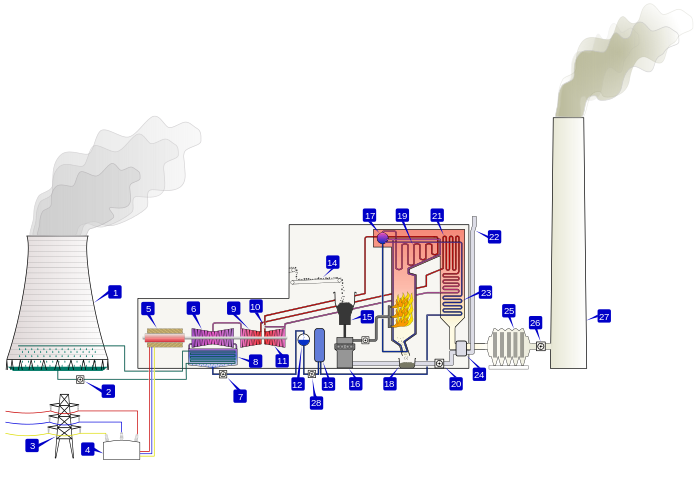

Typical diagram of a coal-fired thermal power station

| 1. Cooling tower | 10. Steam Control valve | 19. Superheater |

| 2. Cooling water pump | 11. High pressure steam turbine | 20. Forced draught (draft) fan |

| 3. Transmission line (3-phase) | 12. Deaerator | 21. Reheater |

| 4. Step-up transformer (3-phase) | 13. Feedwater heater | 22. Combustion air intake |

| 5. Electrical generator (3-phase) | 14. Coal conveyor | 23. Economiser |

| 6. Low pressure steam turbine | 15. Coal hopper | 24. Air preheater |

| 7. Condensate pump | 16. Coal pulverizer | 25. Precipitator |

| 8. Surface condenser | 17. Boiler steam drum | 26. Induced draught (draft) fan |

| 9. Intermediate pressure steam turbine | 18. Bottom ash hopper | 27. Flue-gas stack |

600TL FGD pump

600TL FGD pump

600TL FGD pump