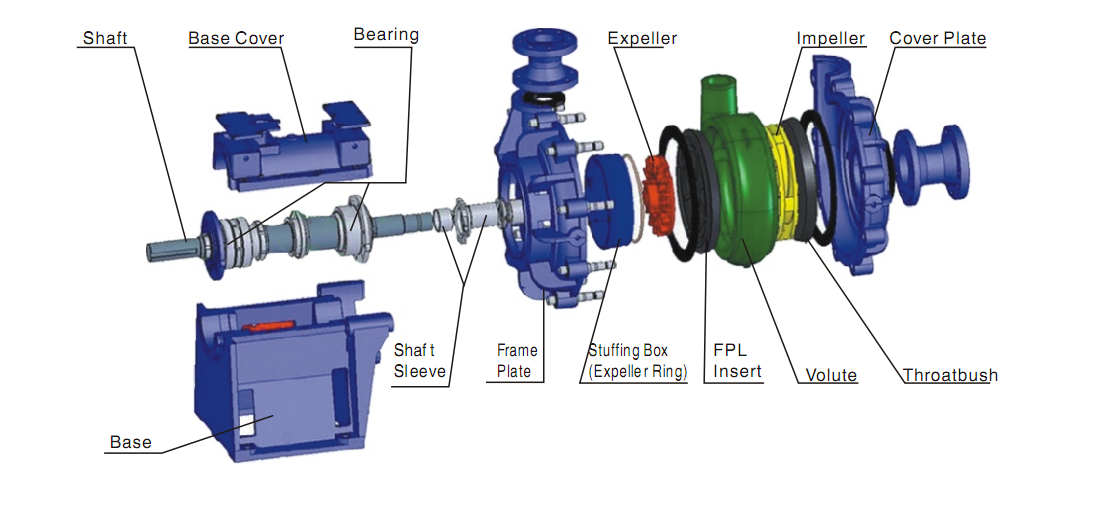

HEAVY DUTY COAL MINE DEWATERING PUMP

BASE – a single piece base with integrated adjustment mechanism for impeller clearance within pump – bearing assembly locks into base using six or eight heavy-duty bolts

BEARING ASSEMBLY – all bearings assembled with highest quality tapered roller bearings in controlled environments to prevent lubricant and housing contamination – oversized shaft diameters and reduced overhang in the wet end contribute to long life and reliability in the field

CASING – split-case design allows for ease of access and maintenance on wet end parts – cast ductile iron with exterior ribbing provides increased pressure ratings and reliable service over time

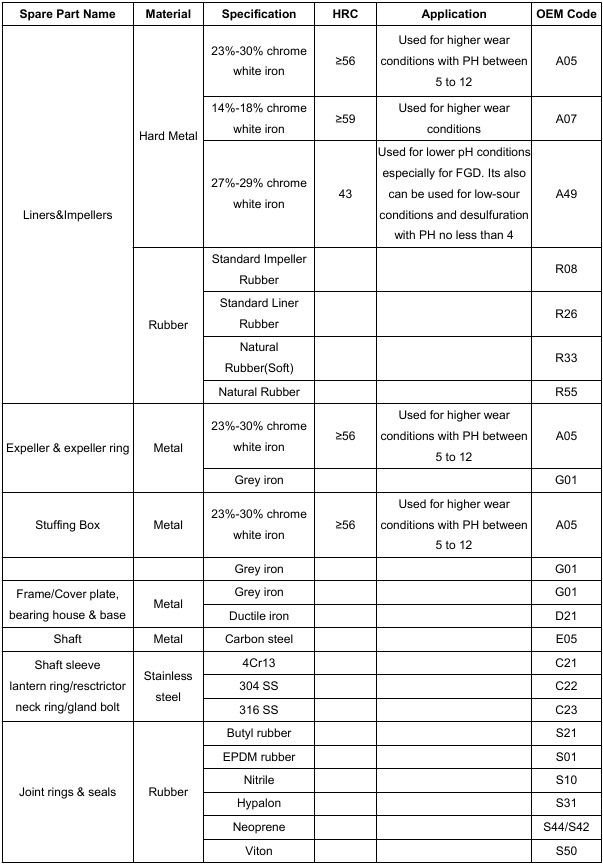

WETTED PARTS

IMPELLERS – hard metal impeller – pump out vanes on rear and front reduce recirculation within pump, and aid in preventing seal contamination – optional castings of straight or semi-Francis vanes offer wider hydraulic options in single sizes

LINERS – heavy-duty hard metal liner – active engineered attachment mechanism to casing via threaded bolts as opposed to unreliable glue

THROATBUSH – adjustable via cotters to account for wear over time and increase efficiency

CHEMICAL COMPATIBILITY – operating PH range from 5 to 12

SHAFT SEALS – LIBRA offers a wide variety of seal options to suit any process requirements

Heavy duty coal mine dewatering pump assembly drawing

This series centrifugal horizontal slurry pumps also named according to the applications when assembled in working conditions, such as, Booster pump, De-Watering Screen Pump, Tailings Pump, Metboom Pump, Feedprep Pump, Scavenger Feed Pump, Re-Cleaner Pump, Ball mill discharge Pump, Ruffer Feed Pump, Transfer to feedprep Pump, Metboom Return Pump, Thickner Underflow Pump, Thickner Tailings Pump, Thickner Underflow Pump, Rinse Pump, Dilute Pump, Re-Cleaner Pump, Rougher Feed Pump, Tailings booster Pump, Mill slurry Pump, Mill feed water Pump, Disc filter basin flushing Pump, Mixing tank slurry Pump, Gas cleaning slurry Pump, Windbox slurry Pump, Pellet hand scrubber slurry pump, Process recycle Pump, Scrubber slurry Pump, Prop pellets undersize Pump, Screen feeder Pump, Furn disch scrubber slurry Pump, Cosmetic recycle water Pump, Backwash Pump, Venturi scrubber slurry pump, Clarifier underflow pump, Pipeline transfer pump etc.