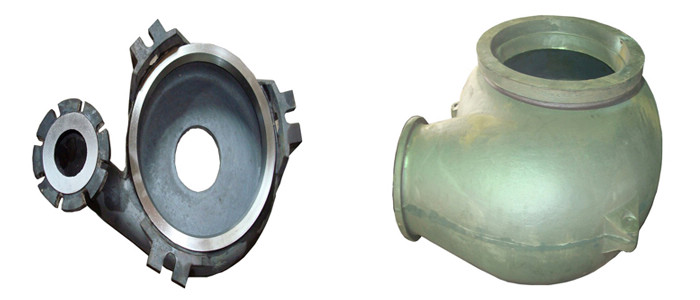

We proudly manufacture quality High Chrome slurry pump casing / sand pump casing and other replacement parts casting work for some famous pump manufactures, which are 100% REVERSE INTERCHANGEABLE, no need to change your stock.

OEM work for high chrome casing is welcomed all the time

1. Hi Chrome Cr27 is a wear resistant white iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy Cr27 is provided by the presence of hard carbides within its micro-structure. Alloy Cr27 is particularly suited to applications where mild corrosion resistance, as well as erosion resistance is required.

2. Cr15Mo3 Marten-sic white iron with moderate erosion resistance.

3. A49 is suitable for low PH corrosion duties, where erosive wear is also a problem. The alloy is particularly suitable for Flue Gas Desulphu-rization(FGD) and other corrosive applications, where the pH is less than 4. The alloy can also be used in other mildly acidic environments. A49 has an erosion resistance similar to that of Ni-Hard 1.

2. Cr15Mo3 Marten-sic white iron with moderate erosion resistance.

3. A49 is suitable for low PH corrosion duties, where erosive wear is also a problem. The alloy is particularly suitable for Flue Gas Desulphu-rization(FGD) and other corrosive applications, where the pH is less than 4. The alloy can also be used in other mildly acidic environments. A49 has an erosion resistance similar to that of Ni-Hard 1.