Slurry Pump Operation Test

1. Check all the slurry pumps’ direction of rotation should be the same with motor

2. The fixed joints should be no loose and lubricating parts should be lubricated according to the technical requirements

3. Indicating instrument and safety protection devices should be sensitive, accurate, and reliable

4. Cranking should be flexible, no abnormal phenomenon

5. The heat pumps should be warm-up in advance, the temperature should rise evenly, the hourly temperature rise should not exceed 50℃. The temperature difference between the piping and pump surface should not be more than 40;

6. Setting the parts to eliminate the temperature rise and connecting cooling water in bypass.

As a rotating machinery and also a pressure vessel, all relevant safety precautions and procedures for a slurry pump should be observed during pump installation, operation and maintenance.

Where auxiliary equipment is associated with a slurry pump (such as motors, drive belts, drive couplings, speed reducers, variable speed drives, etc), all relevant instruction manuals should be consulted, and recommended procedures implemented, during installation, operation and maintenance of the slurry pump system.

Check drive motor rotation of slurry pump prior to fitting of drive belts or couplings. Incorrect motor rotation may cause personnel injury or equipment damage.Do not operate the slurry pump beyond the operating duty specified in the sales conditions without permission, or it may result in injury to personnel or equipment damage.

Do not operate the slurry pump with zero or very low flowrate. Failure to observe this warning could result in vaporization of the pumped fluid, with generation of very high pressures. Injury to personnel or damage to equipment may result from such action.

A slurry pump internally vacuumed shall be isolated for maintenance or operation. Insufficient isolation may result in a flying wheelof the impeller, causing injury to personnel or damage to equipment.

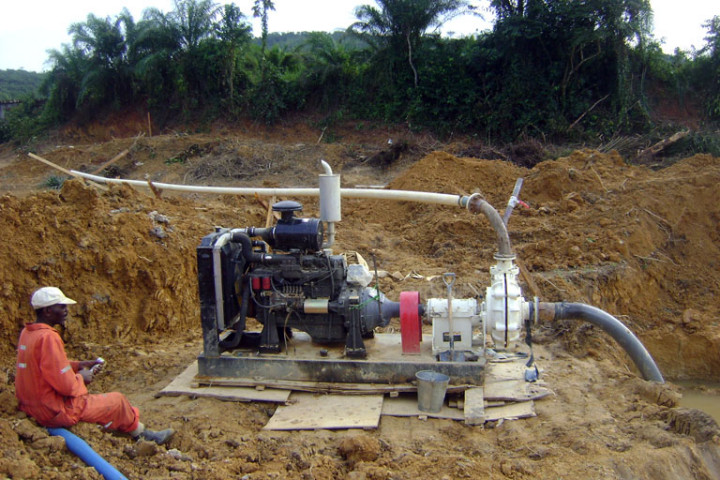

Dewatering pump in Ghana