When come to mine dewatering, the dewatering pump is a must. Bellow we will introduce some kinds of dewatering pump for mining. And after you read the information, you will see our Vertical sand pumps are really good ones for your condition.

Then first we should talk some common pumps to do the work, and their performance, then you will know why should choose our pump for your condition.

Common single-stage or multi-stage horizontal water pump to do drainage work

Need professional worker to do maintenance work

Like multi-stage centrifugal water pump water,there are two units of packing. One in suck end to prevent air in and the other in discharge side to keep no leakage. You need trained worker to check the pump running situation all the time, otherwise you can only notice the pump is not work well after see the rise water level in your site.

There is another problem you have to deal with centrifugal horizontal water pumps, wear out of flow parts.

There are particles in the mine water. And the water pump impeller commonly made of Grey iron.Wear out is a big problem with Grey iron in this condition. So you have to prepare full stock and trained worker to do maintenance work.

And the worst problem is over flow water on mine. This will drive the pump to totally break down. Once you work with aquifers, water faults, there maybe a sudden increase in water inflow or even a flood. The pump and motor are not water proof, no chance to recovery everything. If cause a chain reaction, and sometimes lead to submergence of large accidents.

Submersible pumps

When less gushing, some mining face has begun using submersible pumps. Mining authority had predicted: the next generation pump for dewatering is submersible pumps. Although only a small range of submersible pumps began to apply, but has been prelude.

There are some submersible pumps on market, like well pump, submersible sewage pump. The well pump is thin and long, not good for dewatering condition. Submersible sewage pumps always small power and low head. And they also face the problem, not good wear resistance material. What made it worse for submersible pump is blast problem, this limited its market share.

Supply of products currently on the market, such as water wells with submersible pumps, slender shape, the condition is not suitable for Face. Submersible pumps work surface, generally less power, could not do. In recent years the pump industry launched “Mine submersible pumps,” won the market. However, the fly in the ointment, however, sealing off the motor, easy to water. Because of impellers, pump still using ordinary cast iron, wear is not satisfactory. So submersible pumps in the mine are treated as “consumable equipment”, some units are reluctant to use. More serious is the frequent occurrence of submersible pump itself over the years the explosion, many mines did not dare to use a submersible pump. This accident also limits the application of submersible pumps.

Libra Vertical Sand Pumps

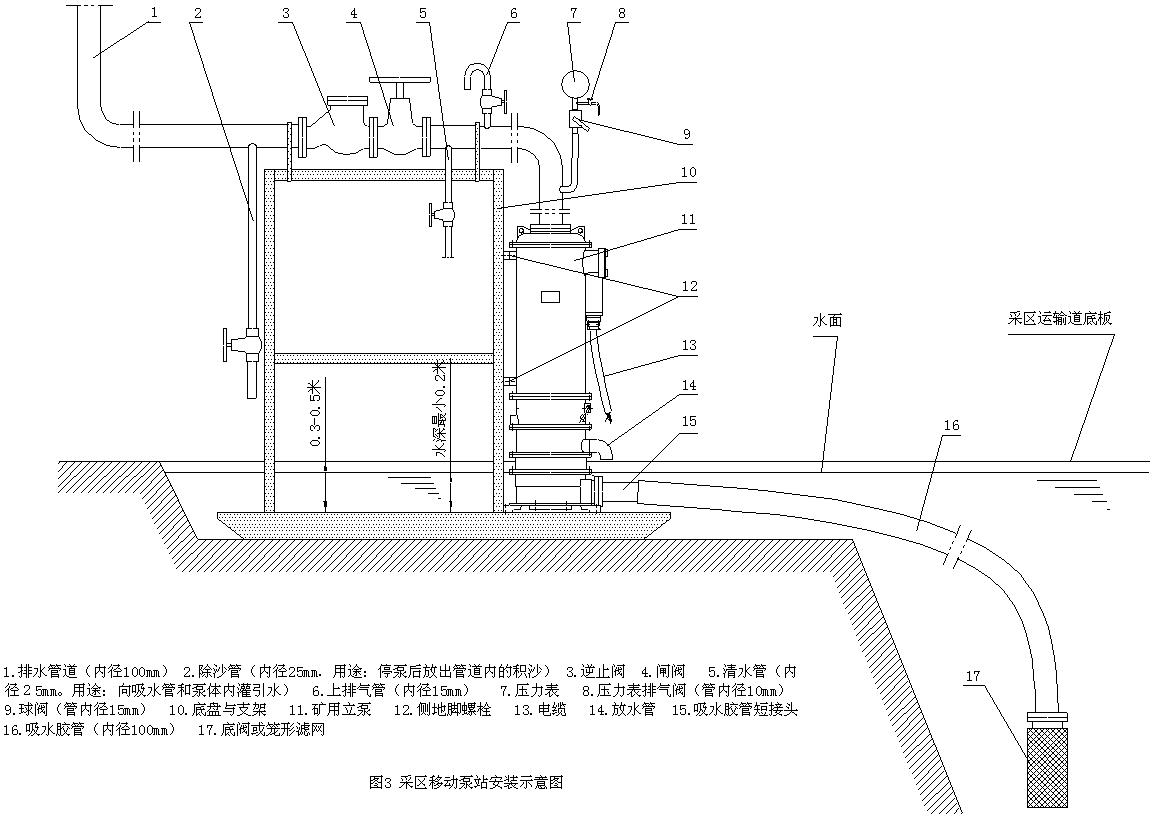

The K Series Vertical Sand Pump has been gradually adopted by many large or middle scale mines and drainage enterprises in last 25 years.Some previous generations have experienced the application tests for dealing with exploded rock and discharging sand, and greatly shorten the drainage cycle. The pump acts as an important role at the moment when water and sand are bursting out.

1.Keep the advantages of centrifugal horizontal water pumps and submersible pumps. Could work on land or under water

2.Libra vertical sand pump can be auto-controlled and work without water. Max 8hours running without water, so no need for watch it all the time

3. Common Material of flow parts is 65Mn, YG8 as a choice, durable for sand slurry dewatering situation

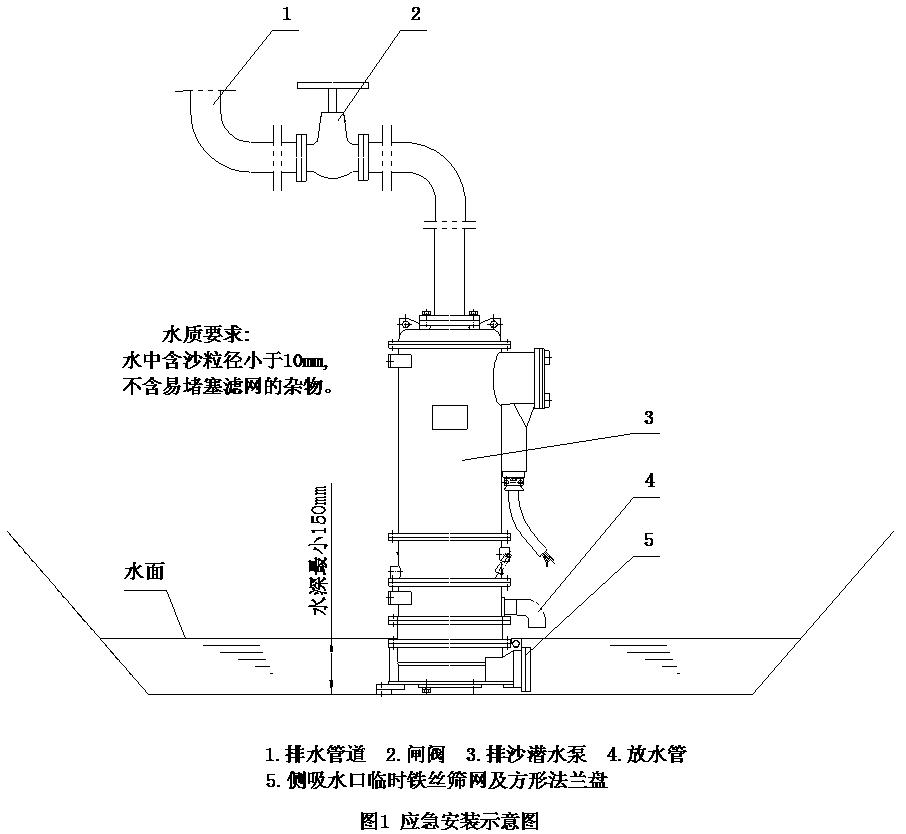

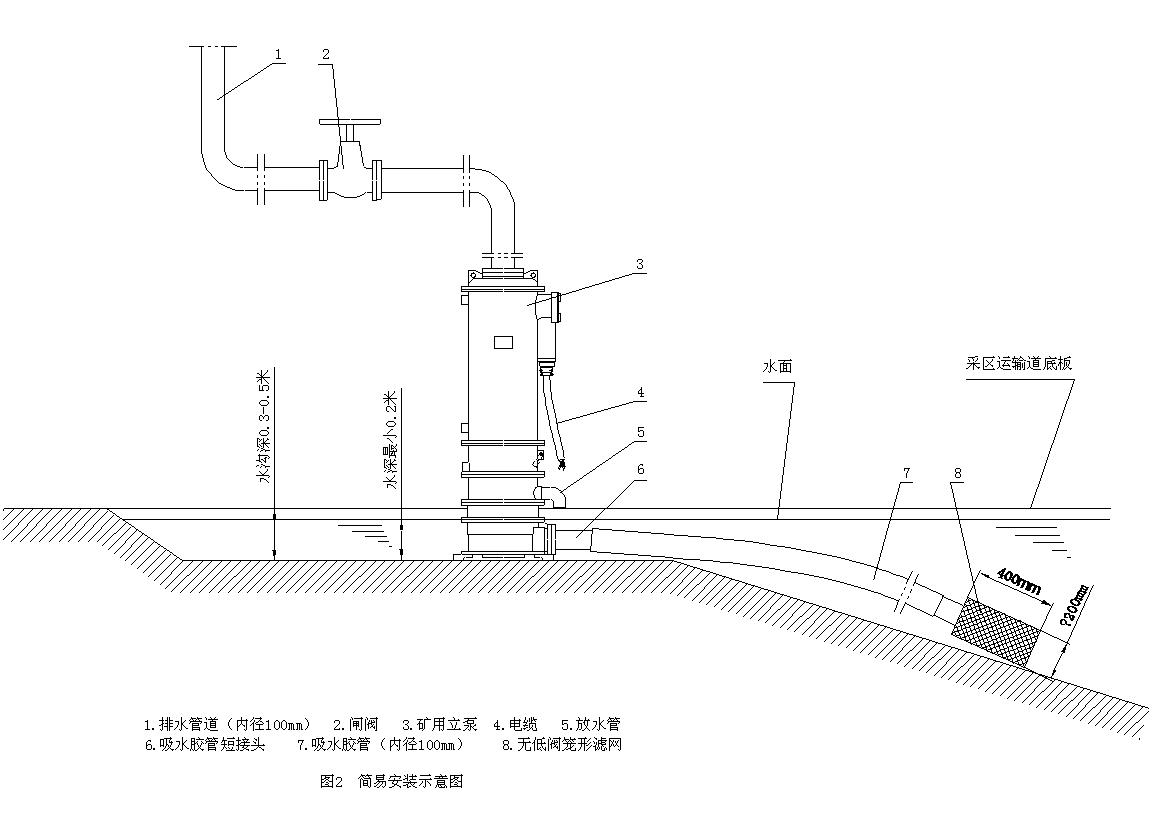

4. Side and Bottom suction pipes are much convenient for connection and installation.

5. There are two relief valves in the pump, its technically solve the self-explode problem.